Prshanth

Solving complex design challenges through data, technology, and 12 years of engineering experience.

Experience Summary

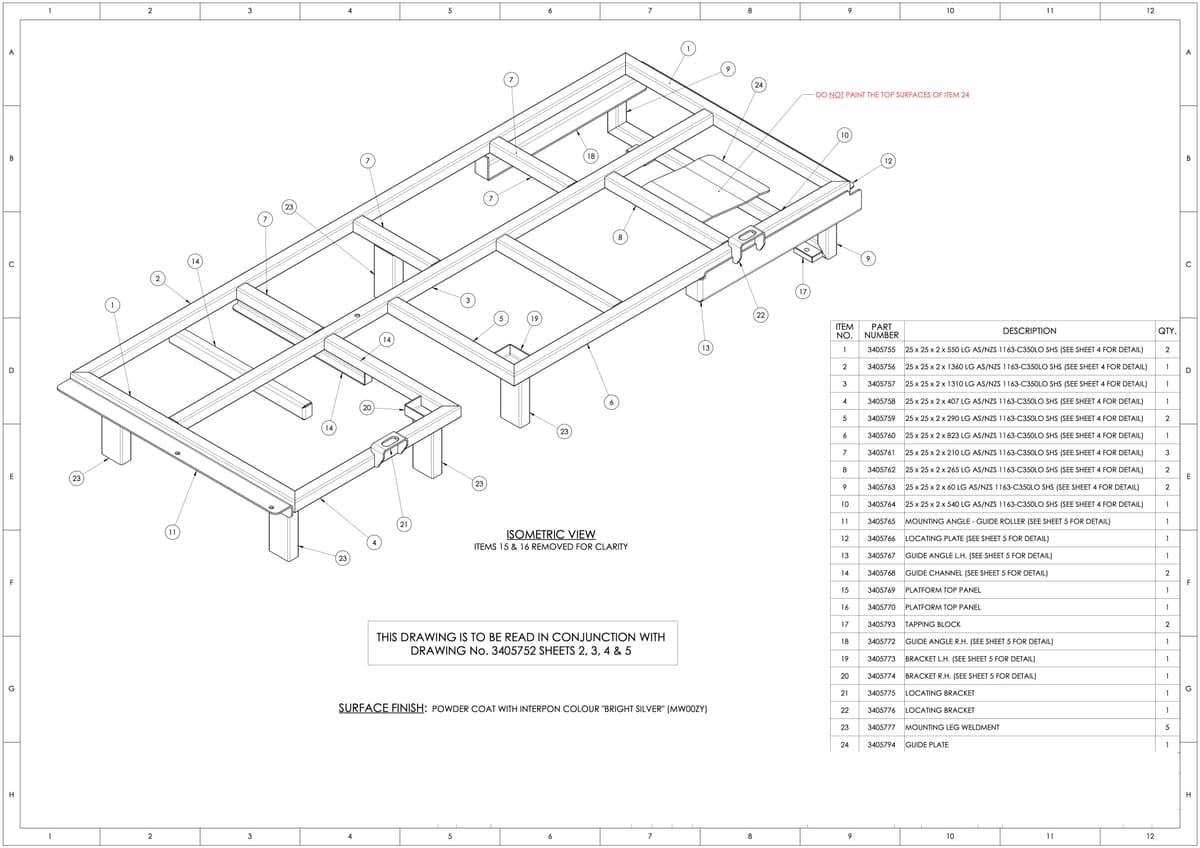

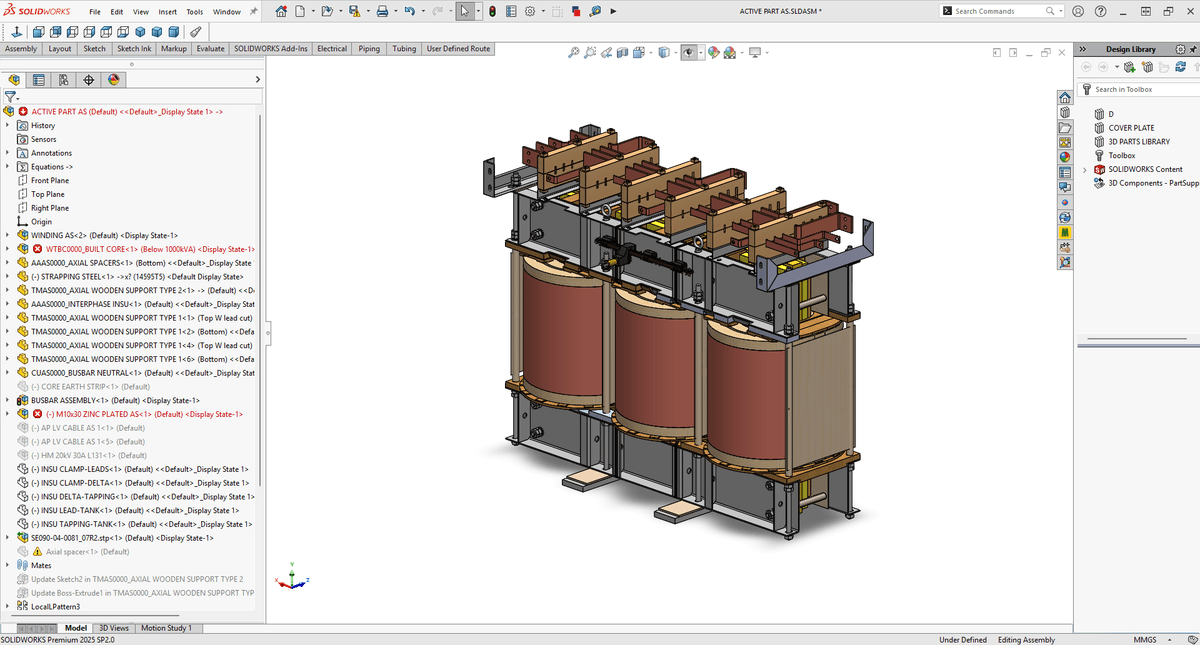

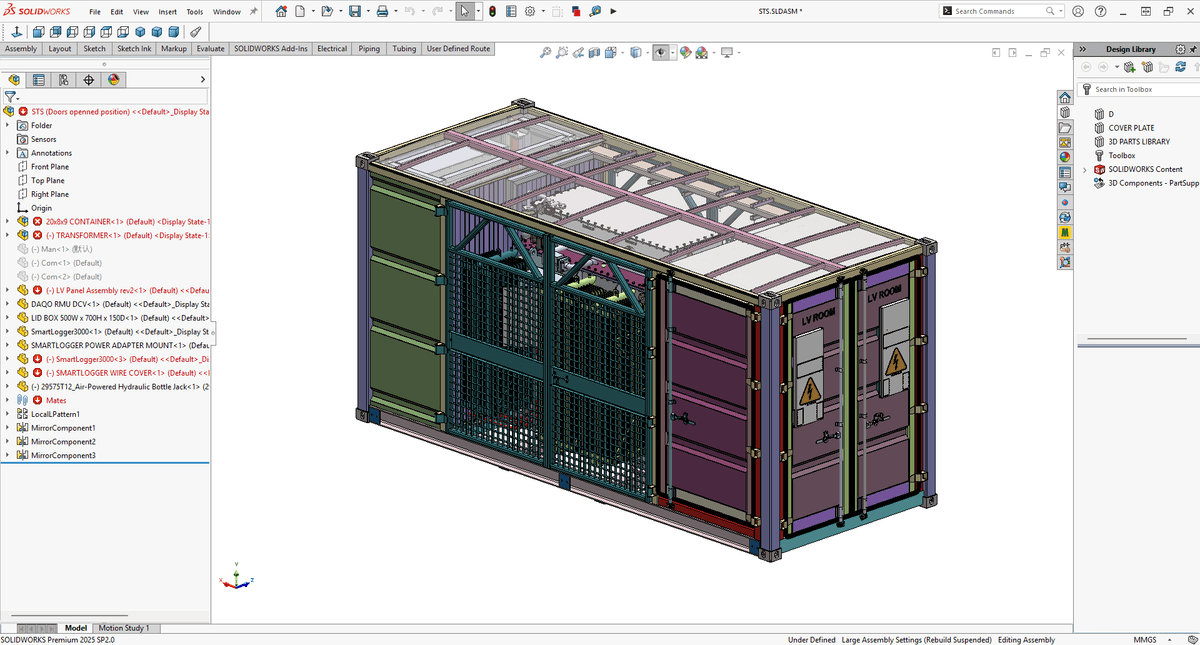

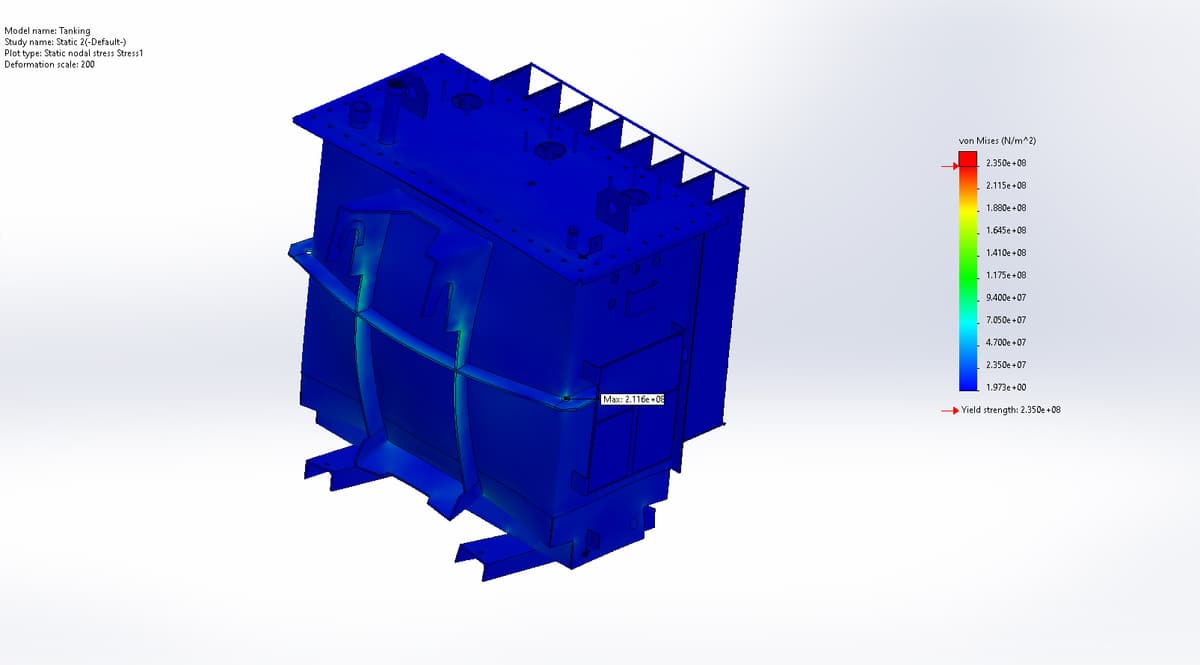

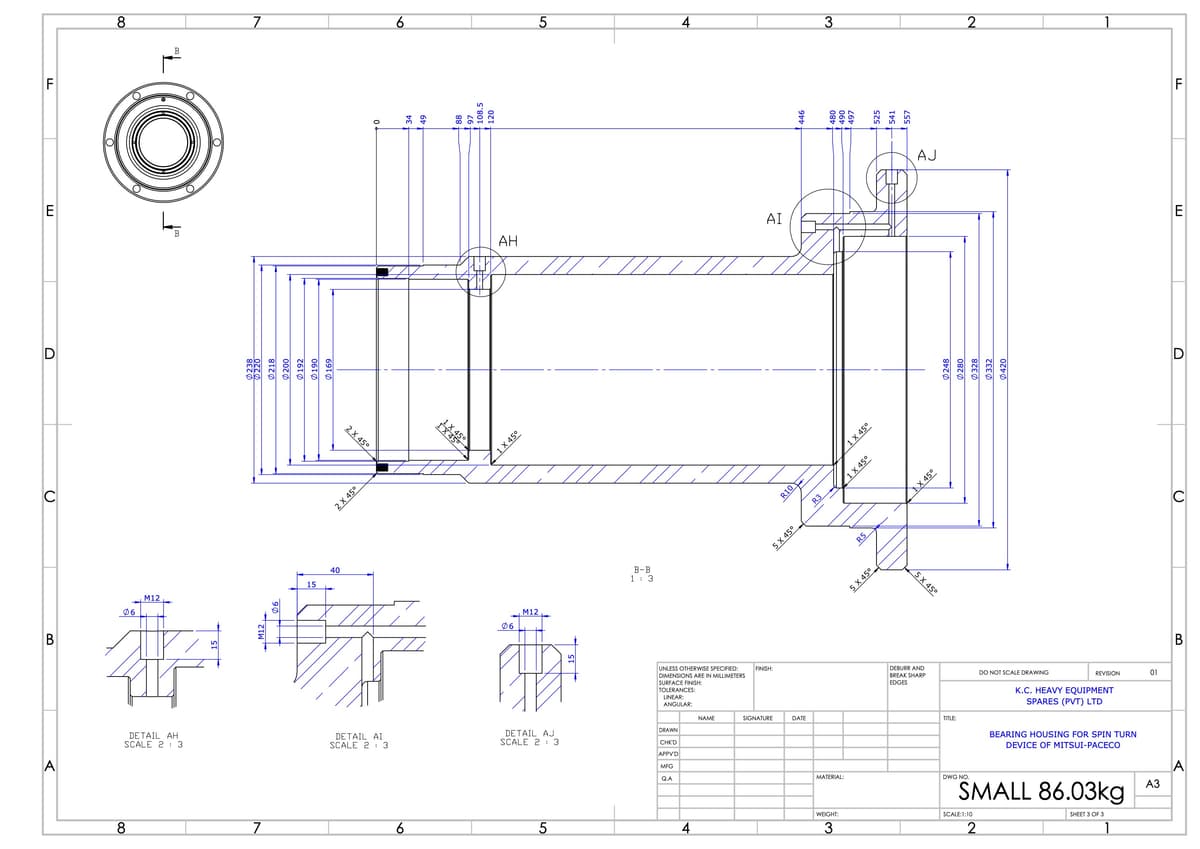

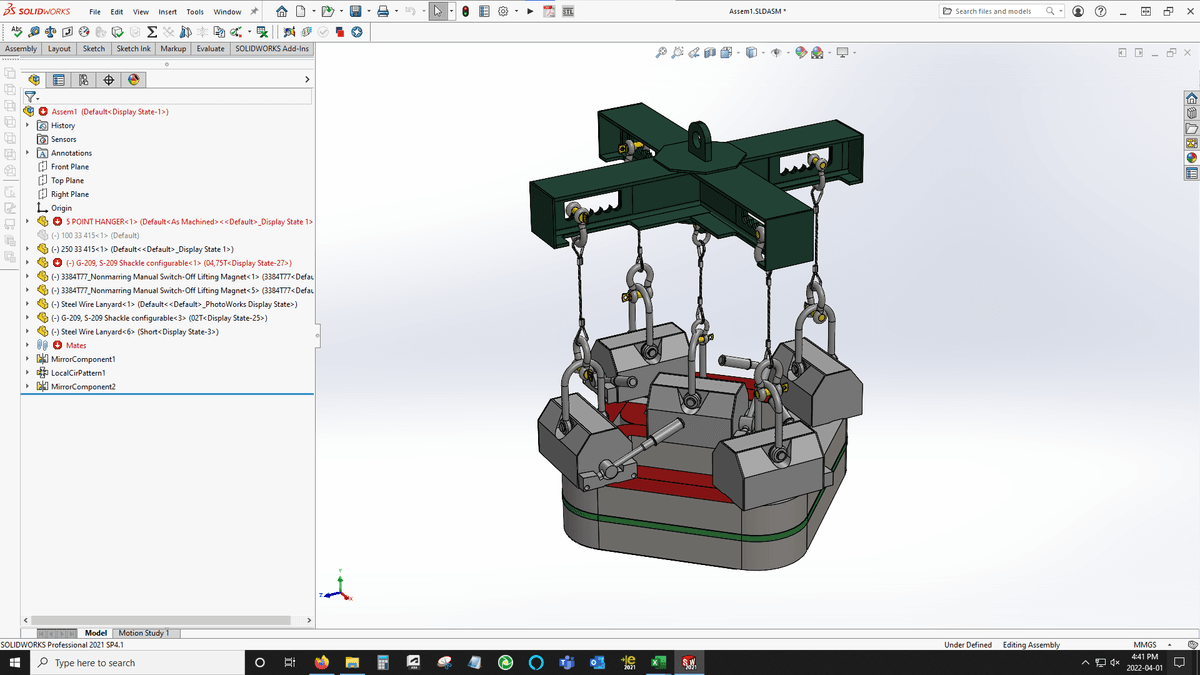

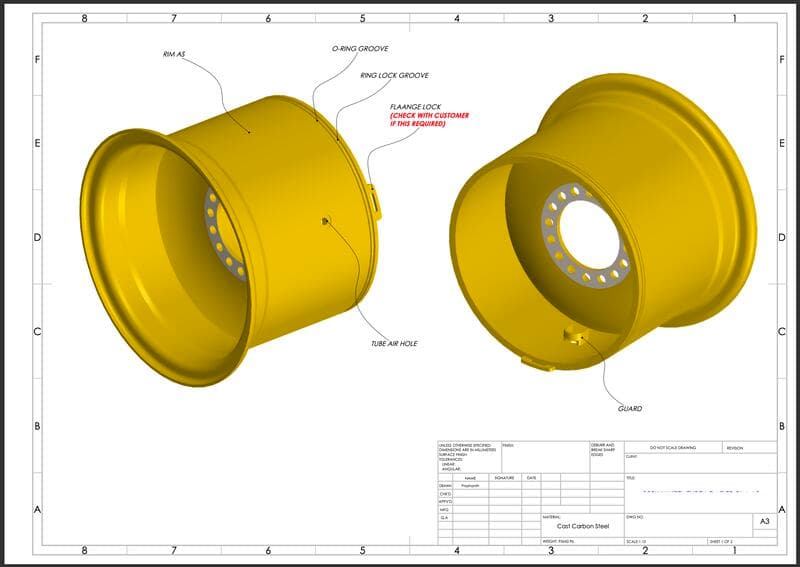

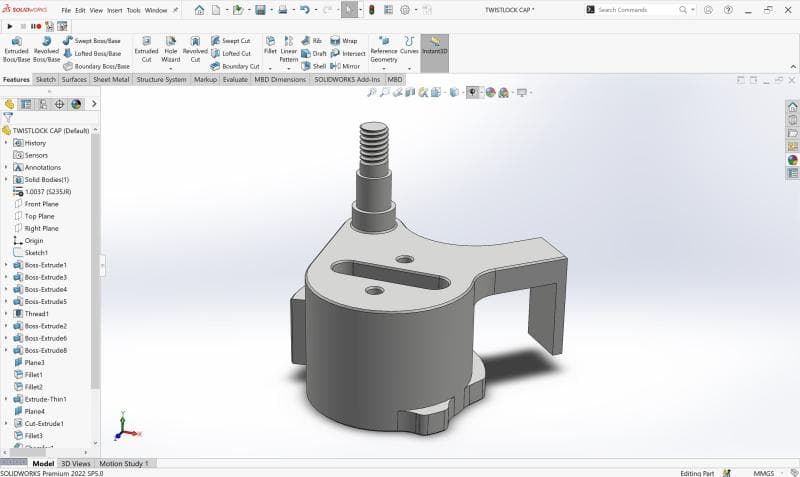

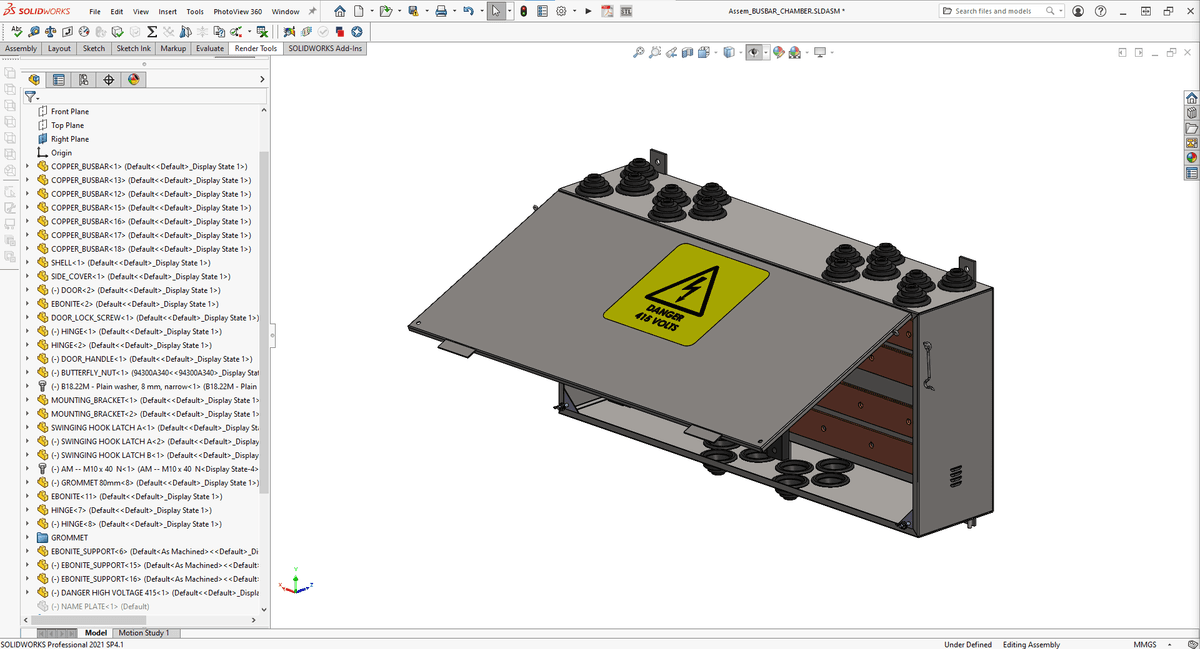

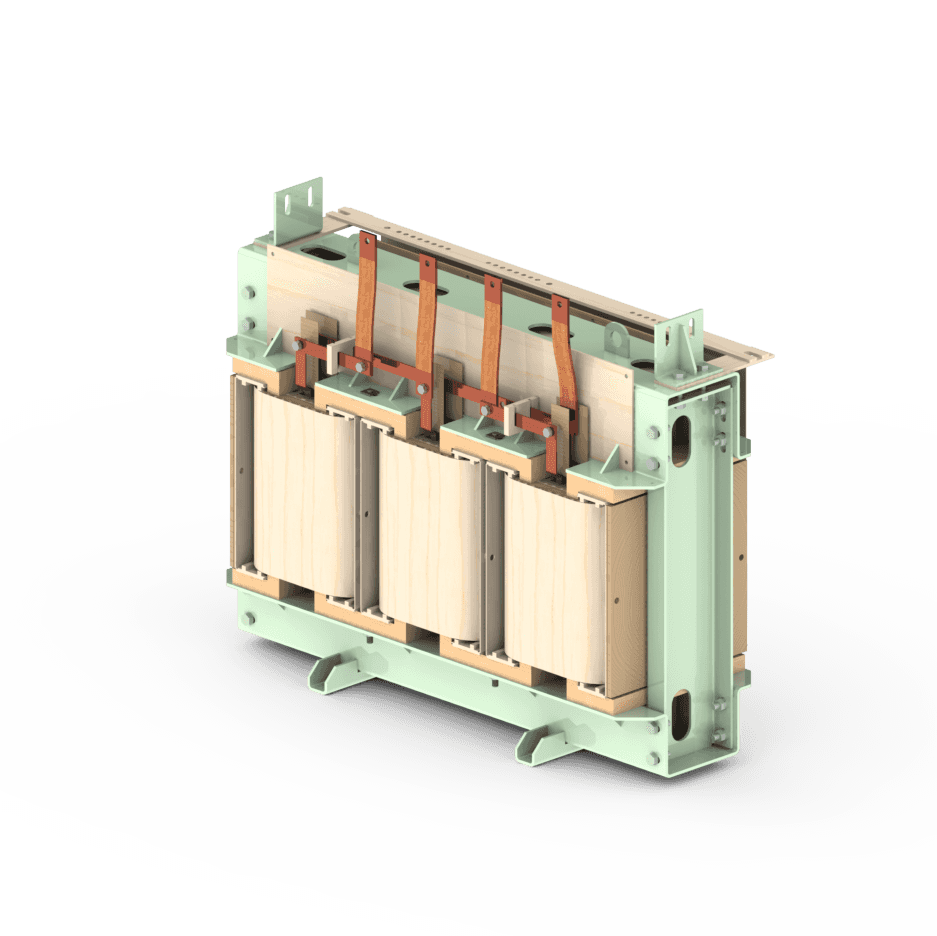

I’m Prashanth, a Mechanical Designer with over 12 years of international experience delivering high-performance, production-ready engineering solutions. Specialized in SolidWorks, I have designed and delivered mechanical systems and transformer assemblies for clients across 🇩🇪 Germany, 🇦🇺 Australia, 🇯🇵 Japan, 🇮🇳 India, 🇦🇪 UAE, 🇶🇦 Qatar, and several 🌍 African regions.

My career spans diverse industries—energy (transformers), heavy machinery, shipbuilding, fuel and transport systems, cement and grain storage, and harbor machinery repair. Through precision engineering and automation, I have helped clients improve manufacturing efficiency, reduce costs, and accelerate delivery timelines.

As a CSWP-certified SolidWorks specialist, I’m proficient in Weldments, Sheet Metal, and Drawing Tools, producing IEC- and ISO-compliant 3D models and documentation. I manage the full project lifecycle—from concept through production—ensuring quality, precision, and on-time execution across multidisciplinary teams.

Beyond design, I specialize in CAD automation, developing DriveWorks configurators and C#-based automation tools that cut engineering workload by up to 90%. I integrate VBA, Google Apps Script, and SAP to automate BOMs, cost sheets, and data pipelines, seamlessly connecting design data with real-time manufacturing and supply-chain systems.

My focus is on building intelligent, repeatable digital workflows that make engineering more accurate, efficient, and scalable. I’m passionate about bridging mechanical engineering and software development to drive Industry 4.0 innovation through smart, automated design ecosystems.

I hold a Diploma in IT and am currently pursuing a Bachelor’s in Information Technology at the University of Moratuwa (expected 2025).

Fluent in C#, VBA, JavaScript, SQL, and Google Apps Script, I bring a software-driven approach to mechanical design.

I built this website to showcase projects that combine engineering precision with digital automation, demonstrating how data and design can work together to solve real-world engineering challenges.

Recent Projects

Showcasing advanced SolidWorks design, precision modeling, and real-world problem-solving.

Design Automation Project Samples

Examples of design automation projects that transformed manual SolidWorks workflows into intelligent, rule-based systems—cutting design time, improving consistency, and enabling rapid customization across product families.

Panel Radiator

Furniture

Distribution Transformer

AI-Assisted CAD Automation System

This project explores the intersection of Artificial Intelligence (AI) and mechanical design by integrating a Large Language Model (LLM) with the SolidWorks API using C#. The system enables users to generate parametric 3D CAD models through natural language commands.

For example, a user can type: “Design a racing bicycle in steel,” and the system automatically produces a production-ready model within SolidWorks.

The architecture operates through a secure sandbox environment, where the AI interprets user input, generates validated C# API code, and executes it safely inside SolidWorks. Each successful model generation is logged — capturing both the input and the resulting output — allowing the system to continuously learn and improve through feedback-driven refinement.

This project demonstrates how AI-driven design automation can transform traditional CAD workflows, making them more intuitive, efficient, and creative. It represents a step toward intent-based modeling, where designers describe what they want — and the system handles how it’s built.

Automating SolidWorks Part Numbering: No More Duplicates!

Tired of every designer on the team naming files differently? In this video, I demo a custom SolidWorks Task Pane add-in I’m developing to solve the "Part1, Part2, Final_Final" chaos.

This tool connects to a SQL database to generate unique, sequential part numbers automatically. Whether you are making your 1st part or your 100th, the system ensures no duplicates and enforces standard prefixes (ASM, FAB, SHT, etc.).

This project shows how automating standard tasks can improve team collaboration and ensure consistency across the design process. Future plans include integrating AI to automatically generate part descriptions based on geometry.

Software I'm Proficient In

Certifications

SOLIDWORKS Professional - Drawing Tools

Dassault Systèmes

SOLIDWORKS Professional - Mechanical Design

Dassault Systèmes

SOLIDWORKS Professional - Sheet Metal

Dassault Systèmes

SOLIDWORKS Professional - Weldments

Dassault Systèmes

Education & Training

Bachelor of Information Technology (Expected 2025)

University of Moratuwa, Sri Lanka

Diploma in Information Technology (2024)

University of Moratuwa, Sri Lanka

DriveWorks On-site Training (2024)

BEACON, Bengaluru, India

CS50: Introduction to Computer Science (2023)

Harvard University (edX)

Toyota Production System / Lean Management (2022)

TPS program

CNC Part Programming & Die/Mould Design (2016)

University of Moratuwa

Design & Drafting (2013)

Thondaman Vocational Training Centre

Languages

Get In Touch

I'm always open to discussing new projects, creative ideas, or opportunities to be part of your vision. Feel free to reach out.

Get in Touch